Introduction: Unveiling the Hidden Pressures

In the heart of every industrial process behind the scenes of scientific breakthroughs and inside the elaborate pipelines of aerospace engineering lies a silent force the vacuum. Imagine a realm without air in which pressure dances on the edge of existence. This is in which vacumetros come into play.

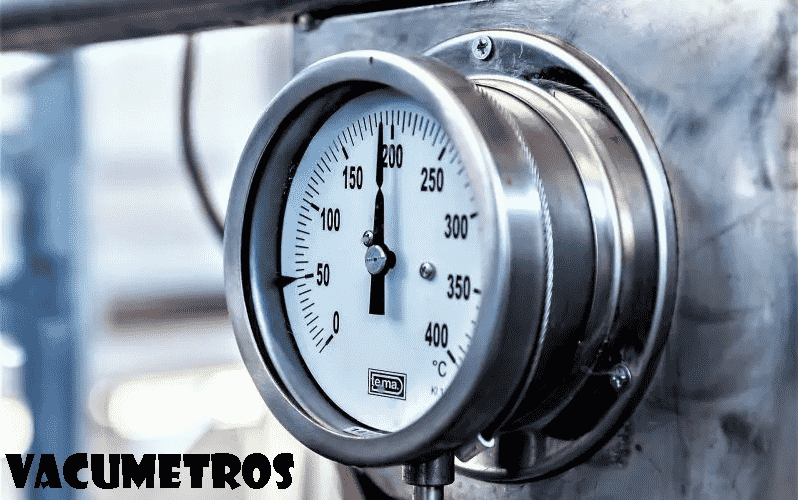

What Are Vacumetros

A Vacumetros usually known as vacuum gauges are essential tools used to measure the level of pressure inside a vacuum or low-pressure environment. These unassuming devices keep the secrets of space exploration scientific diagnostics and precision manufacturing. Picture a scientist adjusting the knobs of a vacuum chamber eyes fixed at the gauge searching for the elusive sweet spot the perfect vacuum.

Some Best Types

-

Rough Vacumetros Gauges:

-

- These gauges are well-suited for rough vacuum measurement in the range of 1 bar to 10⁻³ mbar.

- They provide basic information about vacuum levels and are commonly used in various applications.

-

Mechanical Gauges:

-

- Mechanical vacumetros include several subtypes:

- Bourdon Tube Gauges: These use the movement of an internal tube to measure pressure.

- Diaphragm Gauges: Diaphragm-based gauges are sensitive and suitable for specific applications.

- Bellows Gauges: Bellows elements allow precise measurements in certain pressure ranges.

- Mechanical vacumetros include several subtypes:

-

Thermal Vacumetros:

-

- These vacumetros operate based on the principle of thermal conductivity.

- Examples include Thermocouple and Pirani Vacumetros.

-

Ionization Vacumetros:

-

- Ionization vacumetros rely on ionization processes to measure vacuum levels.

- They are particularly useful in high-vacuum applications.

-

Capacitance Vacumetros:

-

- Capacitance manometers utilize changes in capacitance between two plates to measure pressure.

- They offer accuracy and stability.

-

Cold Cathode Vacumetros:

-

- Cold cathode vacumetros are suitable for low-pressure measurements.

- They operate using ionization and electron emission.

Unveiling the Numbers

1. The Vacuum Gauge Landscape

- Vacuum commonly referred to as vacuum gauges serve as our guides through this pressure wilderness. They measure the elusive vacuum levels within systems ensuring accuracy and reliability.

- From manufacturing plants to research laboratories these unassuming devices silently screen the void allowing us to harness its power.

2. Benefits of Its Using

- Enhanced Efficiency: In the automobile assembly line where precision matters vacumetros ensure that seals fit seamlessly preventing leaks and optimizing overall performance.

- Safety Assurance: In research laboratories where experiments teeter on the edge of discovery its protect towards implosions and sudden pressure shifts.

- Quality Control: In aerospace production where every rivet counts vacuum validate the integrity of sealed booths making sure passenger safety at 30000 feet.

3. Choosing the Right Vacumetros

- Tailoring to Needs: Different applications demand specific types of vacumetros. Professionals must consider precision requirements and finances constraints.

- Leading Brands: Explore the diverse range of models available from budget manufacturers.

Choosing the Right Vacumetros: A Delicate Balance

Selecting the idea vacumetro includes more than just numbers. Consider the application whether it’s a vacuum furnace a medical sterilization chamber or a particle accelerator. Precision subjects but so does budget. The market gives a diverse range of models each catering to unique needs. Choose accurately for the best vacumetro can unlock performance and elevate safety.

Real-World Applications:

- Pharmaceuticals: Picture a lab technician handling vials of life-saving vaccines. The vacumetro whispers assurance the vacuum seal intact the contents protected.

- Automotive Testing: In the heart of a car engine in which combustion meets precision vacumetros display stress fluctuations making sure top-rated performance.

- Space Exploration: As astronauts float in the void vacumetros measure cabin pressure allowing them breathe smooth (literally).

FAQs

-

How often should I calibrate my Vacumetro?

-

- Regular calibration is important to maintain accuracy. Depending on usage and producer recommendations remember calibrating your vacumetro annually or as needs.

-

Can Vacumetros be used in Medical Applications?

-

- Yes positive vacumetros are suitable for clinical use. They play a important role in vacuum-assisted wound recovery sterilization techniques and laboratory applications.

-

Are Digital Vacumetros more accurate than analog ones?

-

- Digital vacumetros usually give best accuracy because of unique electronic measurements. However analog vacumetro remain dependable and fee-powerful for specific applications.

-

What are the common maintenance challenges with Vacumetros?

-

- Common challenges include contamination (cleaning is crucial) sensor drift (requiring recalibration) and damage to fragile components.

-

Where can I find reliable user reviews for Vacumetros?

-

- Look for professional clinical forums industry-unique websites or consult with colleagues who’ve experience using vacumetros.

Conclusion:

And so dear reader next time you gaze at the night sky ponder the vacuum that separates us from the cosmos. The vacumetro unassuming but powerful bridges that hole. But here’s the question: Can we ever certainly hold close the emptiness that surrounds us?